B4c Single Crystal

Silicon Carbide is the only chemical compound of carbon and silicon. It was originally produced by a high temperature electro-chemical reaction of sand and carbon. Silicon carbide is an excellent abrasive and has been produced and made into grinding wheels and other abrasive products for over one hundred years. Today the material has been developed into a high quality technical grade ceramic with very good mechanical properties. It is used in abrasives, refractories, ceramics, and numerous high-performance applications. The material can also be made an electrical conductor and has applications in resistance heating, flame igniters and electronic components. Structural and wear applications are constantly developing.

- We specialize in the production of abrasives, which include Brown Fused Aluminum Oxide (BFA), White Fused Aluminum Oxide (WA), Pink Fused Aluminum Oxide (PA), Black/Green Silicon Carbide (SiC), Boron Carbide (B4C), Single Crystal Aluminum Oxide, Garnet etc. Every year, approximately 30, 000MT is exported to the world market.

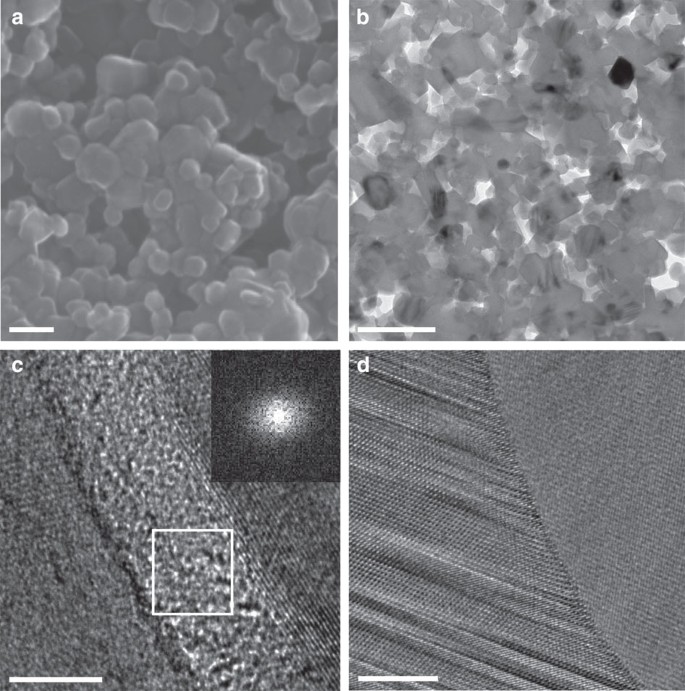

- A single-crystal, or monocrystalline, solid is a material in which the crystal lattice of the entire sample is continuous and unbroken to the edges of the sample, with no grain boundaries.The absence of the defects associated with grain boundaries can give monocrystals unique properties, particularly mechanical, optical and electrical, which can also be anisotropic, depending on the type of.

.Key Silicon Carbide Properties | |

| Low density | |

| High strength | |

| Low thermal expansion | |

| High thermal conductivity | |

| High hardness | |

| High elastic modulus | |

| Excellent thermal shock resistance | |

| Superior chemical inertness | |

.Silicon Carbide Typical Uses | |

| Fixed and moving turbine components | |

| Suction box covers | |

| Seals, bearings | |

| Ball valve parts | |

| Hot gas flow liners | |

| Heat exchangers | |

| Semiconductor process equipment | |

General Silicon Carbide Information

Silicon carbide is composed of tetrahedra of carbon and silicon atoms with strong bonds in the crystal lattice. This produces a very hard and strong material. Silicon carbide is not attacked by any acids or alkalis or molten salts up to 800°C. In air, SiC forms a protective silicon oxide coating at 1200°C and is able to be used up to 1600°C. The high thermal conductivity coupled with low thermal expansion and high strength give this material exceptional thermal shock resistant qualities. Silicon carbide ceramics with little or no grain boundary impurities maintain their strength to very high temperatures, approaching 1600°C with no strength loss. Chemical purity, resistance to chemical attack at temperature, and strength retention at high temperatures has made this material very popular as wafer tray supports and paddles in semiconductor furnaces. The electrical conduction of the material has lead to its use in resistance heating elements for electric furnaces, and as a key component in thermistors (temperature variable resistors) and in varistors (voltage variable resistors).

Additionally, it provided a means of writing conductive graphitic layers on semiconducting B4C single-crystal structures for electronics applications. Processes involving the amorphization of B4C. Processes involving the creation of graphitic contacts. Processing of B4C composites such as sintering, consolidation, etc. These B4C single crystal nanosheets alternate, forming the 3D network nanostructure. The mechanism of formation can be accounted for by in situ reduction reactions along the carbon nanofibers of CBC. Further, low-temperature structural studies of the ground single crystals suggest that even at the nominal B 4 C composition, there is site disorder at the chain-end “C” site. It is most likely that this disorder arises from the presence of boron (or C−B−B) chains.

Silicon Carbide Engineering Properties*

Mechanical | SI/Metric | (Imperial) | |

| Density | gm/cc (lb/ft3) | 3.1 | (193.5) |

| Porosity | % (%) | 0 | (0) |

| Color | — | black | — |

| Flexural Strength | MPa (lb/in2x103) | 550 | (80) |

| Elastic Modulus | GPa (lb/in2x106) | 410 | (59.5) |

| Shear Modulus | GPa (lb/in2x106) | — | — |

| Bulk Modulus | GPa (lb/in2x106) | — | — |

| Poisson’s Ratio | — | 0.14 | (0.14) |

| Compressive Strength | MPa (lb/in2x103) | 3900 | (566) |

| Hardness | Kg/mm2 | 2800 | — |

| Fracture Toughness KIC | MPa•m1/2 | 4.6 | — |

| Maximum Use Temperature (no load) | °C (°F) | 1650 | (3000) |

Thermal | |||

| Thermal Conductivity | W/m•°K (BTU•in/ft2•hr•°F) | 120 | (830) |

| Coefficient of Thermal Expansion | 10–6/°C (10–6/°F) | 4.0 | (2.2) |

| Specific Heat | J/Kg•°K (Btu/lb•°F) | 750 | (0.18) |

Electrical | |||

| Dielectric Strength | ac-kv/mm (volts/mil) | — | semiconductor |

| Dielectric Constant | — | — | — |

| Dissipation Factor | — | — | — |

| Loss Tangent | — | — | — |

| Volume Resistivity | ohm•cm | 102–106 | dopant dependent |

*All properties are room temperature values except as noted.

The data presented is typical of commercially available material and is offered for comparative purposes only. The information is not to be interpreted as absolute material properties nor does it constitute a representation or warranty for which we assume legal liability. User shall determine suitability of the material for the intended use and assumes all risk and liability whatsoever in connection therewith.

Standard Products Custom Products and Services Case Studies Materials

Design Notes Working Together Vision Contact Us Site Map

B4c Single Crystal Necklace

1-908-213-7070

© 2013 Accuratus

B4c Single Crystal

Site Design M. Adams